Logistics is a part of supply chain management that deals with the efficient forward and reverse flow of goods, services, and related information from the point of origin to the point of consumption according to the needs of customers.[2][3] Logistics management is a component that holds the supply chain together.[3] The resources managed in logistics may include tangible goods such as materials, equipment, and supplies, as well as food and other consumable items.

In military logistics, it is concerned with maintaining army supply lines with food, armaments, ammunitions, and spare parts apart from the transportation of troops themselves. Meanwhile, civil logistics deals with the acquisition, movement, and storage of raw materials, semi-finished goods, and finished goods. For organisations that provide services such as garbage collection, mail deliveries, public utilities, and after-sales services, logistical problems also need to be addressed.[2]

Logistics deals with movements of materials or products from one facility to another (e.g. from the production facility to assembly plants to distribution centers); it does not deal with the material flow within the production or assembly plants (e.g. production planning or single-machine scheduling).[2] Logistics occupies a significant amount of the operational cost of an organisation or country. For example, logistical costs of organizations in the United States incurred about 11% of United States national gross domestic product (GDP) in 1997. Such a situation is also similar for the countries in the European Union (EU) where logistics incurred 8.8 to 11.4% of the national GDP in 1993.[2]

The complexity of logistics can be modeled, analyzed, visualized, and optimized by dedicated simulation software. The minimization of the use of resources is a common motivation in all logistics fields. A professional working in the field of logistics management is called a logistician.

A warehouse implementing a pallet rack storage system

Nomenclature[edit]

The term logistics is attested in English from 1846, and is from French: logistique, where it was either coined or popularized by Swiss military officer and writer Antoine-Henri Jomini, who defined it in his Summary of the Art of War (Précis de l’Art de la Guerre). The term appears in the 1830 edition, then titled Analytic Table (Tableau Analytique),[4] and Jomini explains that it is derived from French: logis, lit. ‘lodgings’ (cognate to English lodge), in the terms French: maréchal des logis, lit. ‘marshall of lodgings’ and French: major-général des logis, lit. ‘major-general of lodging’:

Autrefois les officiers de l’état-major se nommaient: maréchal des logis, major-général des logis; de là est venu le terme de logistique, qu’on emploie pour désigner ce qui se rapporte aux marches d’une armée.

Formerly the officers of the general staff were named: marshall of lodgings, major-general of lodgings; from there came the term of logistics [logistique], which we employ to designate those who are in charge of the functioning of an army.

The term is credited to Jomini, and the term and its etymology criticized by Georges de Chambray in 1832, writing:[5]

Logistique: Ce mot me paraît être tout-à-fait nouveau, car je ne l’avais encore vu nulle part dans la littérature militaire. … il paraît le faire dériver du mot logis, étymologie singulière …

Logistic: This word appears to me to be completely new, as I have not yet seen it anywhere in military literature. … he appears to derive it from the word lodgings [logis], a peculiar etymology …

Chambray also notes that the term logistique was present in the Dictionnaire de l’Académie française as a synonym for algebra.

The French word: logistique is a homonym of the existing mathematical term, from Ancient Greek: λογῐστῐκός, romanized: logistikós, a traditional division of Greek mathematics; the mathematical term is presumably the origin of the term logistic in logistic growth and related terms. Some sources give this instead as the source of logistics,[6] either ignorant of Jomini’s statement that it was derived from logis, or dubious and instead believing it was in fact of Greek origin, or influenced by the existing term of Greek origin.

Definition[edit]

Jomini originally defined logistics as:[4]

… l’art de bien ordonner les marches d’une armée, de bien combiner l’ordre des troupes dans les colonnes, les tems [temps] de leur départ, leur itinéraire, les moyens de communications nécessaires pour assurer leur arrivée à point nommé …

… the art of well-ordering the functionings of an army, of well combining the order of troops in columns, the times of their departure, their itinerary, the means of communication necessary to assure their arrival at a named point …

The Oxford English Dictionary defines logistics as «the branch of military science relating to procuring, maintaining and transporting material, personnel and facilities». However, the New Oxford American Dictionary defines logistics as «the detailed coordination of a complex operation involving many people, facilities, or supplies», and the Oxford Dictionary on-line defines it as «the detailed organization and implementation of a complex operation».[7] As such, logistics is commonly seen as a branch of engineering that creates «people systems» rather than «machine systems».

According to the Council of Supply Chain Management Professionals (previously the Council of Logistics Management),[8] logistics is the process of planning, implementing and controlling procedures for the efficient and effective

transportation and storage of goods including services and related information from the point of origin to the point of consumption for the purpose of conforming to customer requirements and includes inbound, outbound, internal and external movements.[9]

Academics and practitioners traditionally refer to the terms operations or production management when referring to physical transformations taking place in a single business location (factory, restaurant or even bank clerking) and reserve the term logistics for activities related to distribution, that is, moving products on the territory. Managing a distribution center is seen, therefore, as pertaining to the realm of logistics since, while in theory, the products made by a factory are ready for consumption they still need to be moved along the distribution network according to some logic, and the distribution center aggregates and processes orders coming from different areas of the territory. That being said, from a modeling perspective, there are similarities between operations management and logistics, and companies sometimes use hybrid professionals, with for example a «Director of Operations» or a «Logistics Officer» working on similar problems. Furthermore, the term «supply chain management» originally referred to, among other issues, having an integrated vision of both production and logistics from point of origin to point of production.[10] All these terms may suffer from semantic change as a side effect of advertising.

Logistics activities[edit]

Logistical activities can be divided into three main areas, namely order processing, inventory management, and freight transportation. Traditionally, order processing was a time-consuming activity that can take up to 70% of the order-cycle time. However, with the advent of new technologies such as bar code scanning, computers, and network connection, orders from customers can quickly reach the seller in no time and the availability of stocks can be checked in real-time. The purpose of having an inventory is to reduce the overall logistical cost while improving service to customers. Having a stockpile of finished goods beforehand can reduce the frequency of transportation to and from the customers and cope with the randomness of customer demands. However, maintaining an inventory requires capital investment in finished goods and maintaining a warehouse. Storage and order picking occupies for most of the warehouse maintenance cost. Freight transportation forms the key part of logistics and allows access to wide markets as goods can be transported to hundred or thousands of kilometers away. Freight transportation accounts for two-thirds of logistical costs and has a major impact on customer service. Transportation policies and warehouse management are closely intertwined.[2]

The rise of commercial transactions through the internet give rise to the need of «e-logistics». Compared to traditional logistics, e-logistics handle parcels that are valued at less than a hundred US dollars to customers scattered at various destinations around the world. In e-logistics, customers’ demands come in waves, when compared to traditional logistics where the demand is consistent.[2]

Inbound logistics is one of the primary processes of logistics concentrating on purchasing and arranging the inbound movement of materials, parts, or unfinished inventory from suppliers to manufacturing or assembly plants, warehouses, or retail stores.

Outbound logistics is the process related to the storage and movement of the final product and the related information flows from the end of the production line to the end user.

Given the services performed by logisticians, the main fields of logistics can be broken down as follows:

- Procurement logistics

- Distribution logistics

- After-sales logistics

- Disposal logistics

- Reverse logistics

- Green logistics

- Global logistics

- Domestics logistics

- Concierge service

- Reliability, availability, and maintainability

- Asset control logistics

- Point-of-sale material logistics

- Emergency logistics

- Production logistics

- Construction logistics

- Capital project logistics

- Digital logistics

- Humanitarian logistics

Loading of a thermal oxidizer at the point of origin en route to a manufacturing plant

Procurement logistics consists of activities such as market research, requirements planning, make-or-buy decisions, supplier management, ordering, and order controlling. The targets in procurement logistics might be contradictory: maximizing efficiency by concentrating on core competences, outsourcing while maintaining the autonomy of the company, or minimizing procurement costs while maximizing security within the supply process.

Advance logistics consists of the activities required to set up or establish a plan for logistics activities to occur.

Global logistics is technically the process of managing the «flow» of goods through what is called a supply chain, from its place of production to other parts of the world. This often requires an intermodal transport system, transport via ocean, air, rail, and truck. The effectiveness of global logistics is measured in the Logistics Performance Index.

Distribution logistics has, as main tasks, the delivery of the finished products to the customer. It consists of order processing, warehousing, and transportation. Distribution logistics is necessary because the time, place, and quantity of production differ with the time, place, and quantity of consumption.[11]

Disposal logistics has as its main function to reduce logistics cost(s) and enhance service(s) related to the disposal of waste produced during the operation of a business.

Reverse logistics denotes all those operations related to the reuse of products and materials. The reverse logistics process includes the management and the sale of surpluses, as well as products being returned to vendors from buyers. It is «the process of planning, implementing, and controlling the efficient, cost-effective flow of raw materials, in-process inventory, finished goods and related information from the point of consumption to the point of origin for the purpose of recapturing value or proper disposal. More precisely, reverse logistics is the process of moving goods from their typical final destination for the purpose of capturing value, or proper disposal. The opposite of reverse logistics is forward logistics.»[This quote needs a citation]

Green logistics describes all attempts to measure and minimize the ecological impact of logistics activities. This includes all activities of the forward and reverse flows. This can be achieved through intermodal freight transport, path optimization, vehicle saturation and city logistics.

RAM logistics (see also Logistic engineering) combines both business logistics and military logistics since it is concerned with highly complicated technological systems for which reliability, availability and maintainability are essential, ex: weapon systems and military supercomputers.

Asset control logistics: companies in the retail channels, both organized retailers and suppliers, often deploy assets required for the display, preservation, promotion of their products. Some examples are refrigerators, stands, display monitors, seasonal equipment, poster stands & frames.

Emergency logistics (or humanitarian logistics) is a term used by the logistics, supply chain, and manufacturing industries to denote specific time-critical modes of transport used to move goods rapidly in the event of an emergency.[12] The reason for enlisting emergency logistics services could be a production delay or anticipated production delay, or an urgent need for specialized equipment to prevent events such as aircraft being grounded (also known as «aircraft on ground»—AOG), ships being delayed, or telecommunications failure. Humanitarian logistics involves governments, the military, aid agencies, donors, non-governmental organizations and emergency logistics services are typically sourced from a specialist provider.[12][13]

The term production logistics describes logistic processes within a value-adding system (ex: factory or a mine). Production logistics aims to ensure that each machine and workstation receives the right product in the right quantity and quality at the right time. The concern is with production, testing, transportation, storage, and supply. Production logistics can operate in existing as well as new plants: since manufacturing in an existing plant is a constantly changing process, machines are exchanged and new ones added, which gives the opportunity to improve the production logistics system accordingly.[14] Production logistics provides the means to achieve customer response and capital efficiency. Production logistics becomes more important with decreasing batch sizes. In many industries (e.g. mobile phones), the short-term goal is a batch size of one, allowing even a single customer’s demand to be fulfilled efficiently. Track and tracing, which is an essential part of production logistics due to product safety and reliability issues, is also gaining importance, especially in the automotive and medical industries.

Construction logistics has been employed by civilizations for thousands of years. As the various human civilizations tried to build the best possible works of construction for living and protection. Now construction logistics has emerged as a vital part of construction. In the past few years, construction logistics has emerged as a different field of knowledge and study within the subject of supply chain management and logistics.

Seven R’s[edit]

The Seven R’s is a popular concept used to enforce best practices in logistics management which consists of the following:[15]

- Right product (including the right information about it)

- (At) right quantity

- Right time

- Right condition

- Right place

- (to) the right customer

- (with the) right (financial) resources

|

|

This section needs expansion with: Graphical representation of Seven R’s. You can help by adding to it. (November 2022) |

Military logistics[edit]

Punjab Regiment uses mules for carrying cargo in Burma during WWII. Animals have been used for logistic purposes by different people throughout history; the Roman army in particular preferred mules over donkeys for their moving capacity.[16]

In military science, maintaining one’s supply lines while disrupting those of the enemy is a crucial—some would say the most crucial—element of military strategy, since an armed force without resources and transportation is defenseless. The historical leaders Hannibal, Alexander the Great, and the Duke of Wellington are considered to have been logistical geniuses: Alexander’s expedition benefited considerably from his meticulous attention to the provisioning of his army,[17] Hannibal is credited to have «taught logistics» to the Romans during the Punic Wars[18] and the success of the Anglo-Portuguese army in the Peninsula War was due to the effectiveness of Wellington’s supply system, despite the numerical disadvantage.[19] The defeat of the British in the American War of Independence and the defeat of the Axis in the African theater of World War II are attributed by some scholars to logistical failures.[20]

Militaries have a significant need for logistics solutions and so have developed advanced implementations. Integrated logistics support (ILS) is a discipline used in military industries to ensure an easily supportable system with a robust customer service (logistic) concept at the lowest cost and in line with (often high) reliability, availability, maintainability, and other requirements, as defined for the project.

In military logistics, Logistics Officers manage how and when to move resources to the places they are needed.

Supply chain management in military logistics often deals with a number of variables in predicting cost, deterioration, consumption, and future demand. The United States Armed Forces’ categorical supply classification was developed in such a way that categories of supply with similar consumption variables are grouped together for planning purposes. For instance, peacetime consumption of ammunition and fuel will be considerably lower than wartime consumption of these items, whereas other classes of supply such as subsistence and clothing have a relatively consistent consumption rate regardless of war or peace.

Some classes of supply have a linear demand relationship: as more troops are added, more supply items are needed; or as more equipment is used, more fuel and ammunition are consumed. Other classes of supply must consider a third variable besides usage and quantity: time. As equipment ages, more and more repair parts are needed over time, even when usage and quantity stay consistent. By recording and analyzing these trends over time and applying them to future scenarios, the US Armed Forces can accurately supply troops with the items necessary at the precise moment they are needed.[21] History has shown that good logistical planning creates a lean and efficient fighting force. The lack thereof can lead to a clunky, slow, and ill-equipped force with too much or too little supply.

Business logistics[edit]

A forklift stacking a logistics provider’s warehouse of goods on pallets

One definition of business logistics speaks of «having the right item in the right quantity at the right time at the right place for the right price in the right condition to the right customer».[22] Business logistics incorporates all industry sectors and aims to manage the fruition of project life cycles, supply chains, and resultant efficiencies.

The term business logistics has evolved since the 1960s[23] due to the increasing complexity of supplying businesses with materials and shipping out products in an increasingly globalized supply chain, leading to a call for professionals called supply chain logisticians.

In business, logistics may have either an internal focus (inbound logistics) or an external focus (outbound logistics), covering the flow and storage of materials from point of origin to point of consumption (see supply-chain management). The main functions of a qualified logistician include inventory management, purchasing, transportation, warehousing, consultation, and the organizing and planning of these activities. Logisticians combine professional knowledge of each of these functions to coordinate resources in an organization.

There are two fundamentally different forms of logistics: one optimizes a steady flow of material through a network of transport links and storage nodes, while the other coordinates a sequence of resources to carry out some project (e.g., restructuring a warehouse).

Nodes of a distribution network[edit]

A distribution network would require several intermediaries to bring consumer or industrial goods from manufacturers to a user. Intermediaries would markup the costs of the products during distribution, but benefit users by providing lower transportation costs than the manufacturers. The number of intermediaries required for the distribution network depends upon the types of goods being distributed. For example, consumer goods such as cosmetics and handicrafts may not require any intermediaries as they can be sold door-to-door or can be obtained from local flea markets. For industrial goods such as raw materials and equipment, intermediaries are not needed because manufacturers can sell a large number of goods to a user. Generally, there are three types of intermediaries, namely: agent/broker, wholesaler, and retailer.[2]

The nodes of a distribution network include:

- Factories where products are manufactured or assembled

- A depot or deposit, a standard type of warehouse for storing merchandise (high level of inventory)

- Distribution centers for order processing and order fulfillment (lower level of inventory) and also for receiving returning items from clients. Typically, distribution centers are way stations for products to be disbursed further down the supply chain. They usually do not ship inventory directly to customers, whereas fulfillment centers do.[citation needed]

- Transit points for cross-docking activities, which consist of reassembling cargo units based on deliveries scheduled (only moving merchandise)

- Traditional «mom-and-pop» retail stores, modern supermarkets, hypermarkets, discount stores or also voluntary chains, consumers’ co-operatives, groups of consumers with collective buying power. Note that subsidiaries will be mostly owned by another company and franchisers, although using other company brands, actually own the point of sale.

Logistic families and metrics[edit]

A logistic family is a set of products that share a common characteristic: weight and volumetric characteristics, physical storing needs (temperature, radiation, etc.), handling needs, order frequency, package size, etc. The following metrics may be used by the company to organize its products in different families:[24]

- Physical metrics used to evaluate inventory systems include stocking capacity, selectivity, superficial use, volumetric use, transport capacity, transport capacity use.

- Monetary metrics used include space holding costs (building, shelving, and services) and handling costs (people, handling machinery, energy, and maintenance).

Other metrics may present themselves in both physical or monetary form, such as the standard inventory turnover.

Handling and order processing[edit]

Unit loads for transportation of luggage at the airport. In this case, the unit load has a protective function.

Unit loads are combinations of individual items which are moved by handling systems, usually employing a pallet of normed dimensions.[25]

Handling systems include: trans-pallet handlers, counterweight handler, retractable mast handler, bilateral handlers, trilateral handlers, AGV and other handlers.

Storage systems include: pile stocking, cell racks (either static or movable), cantilever racks and gravity racks.[26]

Order processing is a sequential process involving: processing withdrawal list, picking (selective removal of items from loading units), sorting (assembling items based on the destination), package formation (weighting, labeling, and packing), order consolidation (gathering packages into loading units for transportation, control and bill of lading).[27]

Picking can be both manual or automated. Manual picking can be both man-to-goods, i.e. operator using a cart or conveyor belt, or goods-to-man, i.e. the operator benefiting from the presence of a mini-load ASRS, vertical or horizontal carousel or from an Automatic Vertical Storage System (AVSS). Automatic picking is done either with dispensers or depalletizing robots.

Sorting can be done manually through carts or conveyor belts, or automatically through sorters.

Transportation[edit]

Consolidating small shipments into large shipments can help to save transportation costs. There are three methods to do this: facility consolidation, multi-stop consolidation, and temporal consolidation. Facility consolidation uses the economics of scale by transporting small shipments over short distances and large shipments over long distances. Multi-stop consolidation makes multiple stops to consolidate small shipments in the case of less-than-truckload shipping. Temporal consolidation adjusts the shipping schedules forwards or backward so as to make a single large shipment rather than several small shipments over time.[2]

Cargo can be consolidated into pallets or containers. There are five basic modes of transport, namely, ship, rail, truck, air, and pipeline operated by different carrier. These shipping methods can be combined in various ways such as intermodal transport (no handling), multimodal transport, and combined transport (minimal road transport). A shipper chooses a carrier by taking into account the total cost of shipment and transit time. Air is the most expensive type of transport, followed by truck, rail, pipeline, and ship.[2]

Cargo can be organized in different shipment categories. Unit loads are usually assembled into higher standardized units such as: ISO containers, swap bodies or semi-trailers. Especially for very long distances, product transportation will likely benefit from using different transportation means: When moving cargo, typical constraints are maximum weight and volume.

Operators involved in transportation include: all train, road vehicles, boats, airplanes companies, couriers, freight forwarders and multi-modal transport operators.

Merchandise being transported internationally is usually subject to the Incoterms standards issued by the International Chamber of Commerce.

Configuration and management[edit]

Push-back rack for motorcycles, a LIFO rack system for storage

In the logistics business, a logistical system is designed at a minimum cost based on the expected customer service level. As the service improves, the number of sales also increased. As service is further improved, more sales are captured from competing providers. Further increase in customer service levels after these only increases sales marginally.[2]

Similarly to production systems, logistic systems need to be properly configured and managed. Actually a number of methodologies have been directly borrowed from operations management such as using Economic Order Quantity models for managing inventory in the nodes of the network.[28] Distribution resource planning (DRP) is similar to MRP, except that it does not concern activities inside the nodes of the network but planning distribution when moving goods through the links of the network.

Traditionally in logistics, configuration may be at the level of the warehouse (node) or at level of the distribution system (network).

Regarding a single warehouse, besides the issue of designing and building the warehouse, configuration means solving a number of interrelated technical-economic problems: dimensioning rack cells, choosing a palletizing method (manual or through robots), rack dimensioning and design, number of racks, number and typology of retrieval systems (e.g. stacker cranes). Some important constraints have to be satisfied: fork and load beams resistance to bending and proper placement of sprinklers. Although picking is more of a tactical planning decision than a configuration problem, it is important to take it into account when deciding the layout of the racks inside the warehouse and buying tools such as handlers and motorized carts since once those decisions are taken they will work as constraints when managing the warehouse, the same reasoning for sorting when designing the conveyor system or installing automatic dispensers.

Configuration at the level of the distribution system concerns primarily the problem of location of the nodes in geographic space and distribution of capacity among the nodes. The first may be referred to as facility location (with the special case of site selection) while the latter to as capacity allocation. The problem of outsourcing typically arises at this level: the nodes of a supply chain are very rarely owned by a single enterprise. Distribution networks can be characterized by numbers of levels, namely the number of intermediary nodes between supplier and consumer:

- Direct store delivery, i.e. zero levels

- One level network: central warehouse

- Two level network: central and peripheral warehouses

This distinction is more useful for modeling purposes, but it relates also to a tactical decision regarding safety stocks: considering a two-level network, if safety inventory is kept only in peripheral warehouses then it is called a dependent system (from suppliers), if safety inventory is distributed among central and peripheral warehouses it is called an independent system (from suppliers).[24] Transportation from producer to the second level is called primary transportation, from the second level to a consumer is called secondary transportation.

Although configuring a distribution network from zero is possible, logisticians usually have to deal with restructuring existing networks due to presence of an array of factors: changing demand, product or process innovation, opportunities for outsourcing, change of government policy toward trade barriers, innovation in transportation means (both vehicles or thoroughfares), the introduction of regulations (notably those regarding pollution) and availability of ICT supporting systems (e.g. ERP or e-commerce).

Once a logistic system is configured, management, meaning tactical decisions, takes place, once again, at the level of the warehouse and of the distribution network. Decisions have to be made under a set of constraints: internal, such as using the available infrastructure, or external, such as complying with the given product shelf lifes and expiration dates.

At the warehouse level, the logistician must decide how to distribute merchandise over the racks. Three basic situations are traditionally considered: shared storage, dedicated storage (rack space reserved for specific merchandise) and class-based storage (class meaning merchandise organized in different areas according to their access index).

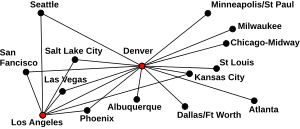

Airline logistic network. Denver works as a hub in the network.

Picking efficiency varies greatly depending on the situation.[27] For a man to goods situation, a distinction is carried out between high-level picking (vertical component significant) and low-level picking (vertical component insignificant). A number of tactical decisions regarding picking must be made:

- Routing path: standard alternatives include transversal routing, return routing, midpoint routing, and largest gap return routing

- Replenishment method: standard alternatives include equal space supply for each product class and equal time supply for each product class.

- Picking logic: order picking vs batch picking

At the level of the distribution network, tactical decisions involve mainly inventory control and delivery path optimization. Note that the logistician may be required to manage the reverse flow along with the forward flow.

Warehouse management system and control[edit]

Although there is some overlap in functionality, warehouse management systems (WMS) can differ significantly from warehouse control systems (WCS). Simply put, a WMS plans a weekly activity forecast based on such factors as statistics and trends, whereas a WCS acts like a floor supervisor, working in real-time to get the job done by the most effective means. For instance, a WMS can tell the system that it is going to need five of stock-keeping unit (SKU) A and five of SKU B hours in advance, but by the time it acts, other considerations may have come into play or there could be a logjam on a conveyor. A WCS can prevent that problem by working in real-time and adapting to the situation by making a last-minute decision based on current activity and operational status. Working synergistically, WMS and WCS can resolve these issues and maximize efficiency for companies that rely on the effective operation of their warehouse or distribution center.[29]

Logistics outsourcing[edit]

Logistics outsourcing involves a relationship between a company and an LSP (logistic service provider), which, compared with basic logistics services, has more customized offerings, encompasses a broad number of service activities, is characterized by a long-term orientation, and thus has a strategic nature.[30]

Outsourcing does not have to be complete externalization to an LSP, but can also be partial:

- A single contract for supplying a specific service on occasion

- Creation of a spin-off

- Creation of a joint venture

Third-party logistics (3PL) involves using external organizations to execute logistics activities that have traditionally been performed within an organization itself.[31] According to this definition, third-party logistics includes any form of outsourcing of logistics activities previously performed in house. For example, if a company with its own warehousing facilities decides to employ external transportation, this would be an example of third-party logistics. Logistics is an emerging business area in many countries. External 3PL providers have evolved from merely providing logistics capabilities to becoming real orchestrators of supply chains that create and sustain a competitive advantage, thus bringing about new levels of logistics outsourcing.[32]

The concept of a fourth-party logistics (4PL) provider was first defined by Andersen Consulting (now Accenture) as an integrator that assembles the resources, planning capabilities, and technology of its own organization and other organizations to design, build, and run comprehensive supply chain solutions. Whereas a third-party logistics (3PL) service provider targets a single function, a 4PL targets management of the entire process. Some have described a 4PL as a general contractor that manages other 3PLs, truckers, forwarders, custom house agents, and others, essentially taking responsibility of a complete process for the customer.

Horizontal alliances between logistics service providers[edit]

Horizontal business alliances often occur between logistics service providers, i.e., the cooperation between two or more logistics companies that are potentially competing.[33] In a horizontal alliance, these partners can benefit twofold. On one hand, they can «access tangible resources which are directly exploitable». In this example extending common transportation networks, their warehouse infrastructure and the ability to provide more complex service packages can be achieved by combining resources. On the other hand, partners can «access intangible resources, which are not directly exploitable». This typically includes know-how and information and, in turn, innovation.[33]

Logistics automation[edit]

Logistics automation is the application of computer software or automated machinery to improve the efficiency of logistics operations. Typically, this refers to operations within a warehouse or distribution center with broader tasks undertaken by supply chain engineering systems and enterprise resource planning systems.

Industrial machinery can typically identify products through either barcode or RFID technologies. Information in traditional bar codes is stored as a sequence of black and white bars varying in width, which when read by laser is translated into a digital sequence, which according to fixed rules can be converted into a decimal number or other data. Sometimes information in a bar code can be transmitted through radio frequency, more typically radio transmission is used in RFID tags. An RFID tag is a card containing a memory chip and an antenna that transmits signals to a reader. RFID may be found on merchandise, animals, vehicles, and people as well.

Logistics: profession and organizations[edit]

A logistician is a professional logistics practitioner. Professional logisticians are often certified by professional associations. One can either work in a pure logistics company, such as a shipping line, airport, or freight forwarder, or within the logistics department of a company. However, as mentioned above, logistics is a broad field, encompassing procurement, production, distribution, and disposal activities. Hence, career perspectives are broad as well.

A new trend[as of?] in the industry is the 4PL, or fourth-party logistics, firms, consulting companies offering logistics services.

Some universities and academic institutions train students as logisticians, offering undergraduate and postgraduate programs. A university with a primary focus on logistics is Kühne Logistics University in Hamburg, Germany. It is non-profit and supported by Kühne-Foundation of the logistics entrepreneur Klaus Michael Kühne.

The Chartered Institute of Logistics and Transport (CILT), established in the United Kingdom in 1919, received a Royal Charter in 1926. The Chartered Institute is one of the professional bodies or institutions for the logistics and transport sectors that offer professional qualifications or degrees in logistics management. CILT programs can be studied at centers around the UK, some of which also offer distance learning options.[34] The institute also have overseas branches namely The Chartered Institute of Logistics & Transport Australia (CILTA)[35] in Australia and Chartered Institute of Logistics and Transport in Hong Kong (CILTHK)[36] in Hong Kong. In the UK, Logistics Management programs are conducted by many universities and professional bodies such as CILT. These programs are generally offered at the postgraduate level.

The Global Institute of Logistics[37] established in New York in 2003 is a think tank for the profession and is primarily concerned with intercontinental maritime logistics. It is particularly concerned with container logistics and the role of the seaport authority in the maritime logistics chain.

The International Association of Public Health Logisticians (IAPHL)[38] is a professional network that promotes the professional development of supply chain managers and others working in the field of public health logistics and commodity security, with particular focus on developing countries. The association supports logisticians worldwide by providing a community of practice, where members can network, exchange ideas, and improve their professional skills.

Key Issue for Logistics Indusry[edit]

Environmental sustainability is another key issue for the logistics industry. With transportation accounting for a significant portion of global greenhouse gas emissions, logistics companies are under increasing pressure to reduce their environmental impact. This has led to the development of alternative fuels, such as electric and hydrogen-powered vehicles, as well as the use of renewable energy sources for logistics facilities.

Logistics museums[edit]

There are many museums in the world which cover various aspects of practical logistics. These include museums of transportation, customs, packing, and industry-based logistics. However, only the following museums are fully dedicated to logistics:

General logistics

- Logistics Museum (Saint Petersburg, Russia)[39]

- Museum of Logistics (Tokyo, Japan)[40]

- Beijing Wuzi University Logistics Museum (Beijing, China)

Military logistics

- Royal Logistic Corps Museum (Surrey, England, United Kingdom)

- The Canadian Forces Logistics Museum (Montreal, Quebec, Canada)[41]

- Logistics Museum (Hanoi, Vietnam)

See also[edit]

- Automated identification and data capture

- Document automation in supply chain management and logistics

- Field inventory management

- Freight claim

- Freight forwarder

- Incoterms

- Containerization

- Integrated Service Provider

- Inventory management software

- Performance-based logistics

- Physical inventory

- Sales territory

- Storage management system

- Blockchain

- Dutch flower bucket

- Self-driving truck

- Automated storage and retrieval system

- Automated guided vehicle

References[edit]

- ^ Jon Hurdle (13 May 2021). «Report details surge in warehouse construction…». NJ Spotlight News. Retrieved 3 January 2023.

In South Jersey, the area has become the «epicenter» of warehouse construction in the greater Philadelpia region..’Activity in the Southern New Jersey industrial market continues to amaze,’ the report said.

- ^ a b c d e f g h i j Ghiani, Gianpaolo; Laporte, Gilbert; Musmanno, Roberto (2004). Introduction to Logistics Systems Planning and Control. John Wiley & Sons. p. 1,5,10-15. ISBN 9780470849170. Retrieved 8 January 2023.

- ^ a b Kozlenkova, Irina V.; Hult, G. Tomas M.; Lund, Donald J.; Mena, Jeannette A.; Kekec, Pinar (December 2015). «The Role of Marketing Channels in Supply Chain Management». Journal of Retailing. 91 (4): 586–609. doi:10.1016/j.jretai.2015.03.003.

Logistics refers to «that part of supply chain management that plans, implements, and controls the efficient, effective forward and reverse flow and storage of goods, services, and related information between the point of origin and the point of consumption in order to meet customers’ requirements»

- ^ a b Baron de Jomini (1830). Tableau Analytique des principales combinaisons De La Guerre, Et De Leurs Rapports Avec La Politique Des États: Pour Servir D’Introduction Au Traité Des Grandes Opérations Militaires. p. 74.

- ^ Chambray [in French] (1832). «Observation sur Le Tableau Analytique des principales combinaisons De La Guerre, Et De Leurs Rapports Avec La Politique Des États: Pour Servir D’Introduction Au Traité Des Grandes Opérations Militaires par le général Jomini». Le Spectateur militaire: Recueil de science, d’art et d’histoire militaires (in French). 13: 19.

- ^ Tepic, J.; Tanackov, I.; Stojić, Gordan (2011). «Ancient logistics – historical timeline and etymology» (PDF). Technical Gazette. 18 (3). S2CID 42097070. Archived from the original (PDF) on 9 March 2019.

- ^ Oxford Dictionaries[dead link]. Retrieved 21 February 2012.

- ^ Material Handling & Logistics News http://mhlnews.com/global-supply-chain/council-logistics-management-become-council-supply-chain-management-professional

- ^ CSCMP glossary «Archived copy» (PDF). Archived from the original (PDF) on 22 May 2016. Retrieved 10 September 2013.

{{cite web}}: CS1 maint: archived copy as title (link) - ^ V. Misra, M.I. Kahn, U.K. Singh, Supply Chain Management Systems: Architecture, Design and Vision, North American Business Press 2010 http://www.na-businesspress.com/jsis/misraweb.pdf

- ^ Hofmann, Sebastian. «Distribution logistics — definition, basics, examples». Retrieved 3 March 2022.

- ^ a b Cozzolino Alessandra, Humanitarian Logistics and Supply Chain Management, In Humanitarian Logistics, Springer Berlin Heidelberg 2012

- ^ L. Torre, I.S. Dolinskaya, K.R. Smilowitz, Disaster relief routing: Integrating research and practice Socio-Economic Planning Sciences vol46, March 2012

- ^ Nyhuis P., Wiendahi Hans-Peter, Fundamentals of Production Logistics, Springer Berlin Heidelberg 2009

- ^ What is Logistics Management? Meaning, Importance, Basic Functions & Strategies on YouTube

- ^ J.P. Roth, The logistics of Roman army at war (264 B.C. -A.D. 235) https://www.academia.edu/2450333/Logistics_of_the_Roman_Army_at_War

- ^ Donald W. Engels, Alexander the Great and the Logistics of the Macedonian Army, University of California 1980

- ^ Ayrault Dodge Theodore, Hannibal: A History of the Art of War Among the Carthaginians and Romans Down to the Battle of Pydna, 168 BC. Da Capo Press. 1995

- ^ Troy T. Kirby, The Duke of Wellington and the Supply System During the Peninsula War, CreateSpace Independent Publishing Platform 2014

- ^ Roger Morriss, «Colonization, Conquest, and the Supply of Food and Transport: The Reorganization of Logistics Management, 1780–1795,» War in History, (July 2007), 14#3 pp 310–324,

- ^ Cloutier, Peter J.; Frank, Brian K. (July–August 2009). «The Joint Logistics Analysis Tool». Army Logistician. 41 (4).

- ^ Mallik, Susan (2010). «Customer Service in Supply Chain Management». In Hossein Bidgoil (ed.). The Handbook of Technology Management: Supply Chain Management, Marketing and Advertising, and Global Management, vol 2 (1 ed.). Hoboken, New Jersey: John Wiley & Sons. p. 104. ISBN 978-0-470-24948-2.

- ^ McGinnis M. A., Military Logistics: Insights for Business Logistics, International Journal of Physical Distribution & Logistics Management Vol 22, 1992

- ^ a b Ruggeri, R.; Perego, A. (2001). Esercitazioni e temi d’esame di Logistica Industriale (in Italian). CUSL. ISBN 8881320150.

- ^ ISO 6780:2003 – Flat pallets for intercontinental materials handling – Principal dimensions and tolerances.

- ^ Lambert D., Stock J., Ellram L., Fundamentals of Logistics, McGraw-Hill 1998

- ^ a b D.F. Bozutti, M.A. Bueno-Da-Costa, R. Ruggeri, Logística: Visão Global e Picking, EdUFSCar 2010

- ^ Waters D., Logistics: An Introduction to Supply Chain Management, Palgrave Macmillan 2003

- ^ John T. Phelan, Jr. P.E. Supply & Demand Chain Executive. Enom, Inc. ;

- ^ Wallenburg, Carl Marcus; Cahill, David L.; Michael Knemeyer, A.; Goldsby, Thomas J. (2011). «Commitment and Trust as Drivers of Loyalty in Logistics Outsourcing Relationships: Cultural Differences Between the United States and Germany». Journal of Business Logistics. 32: 83–98. doi:10.1111/j.2158-1592.2011.01008.x.

- ^ Baziotopoulos (2008). «An Investigation of Logistics Outsourcing Practices in the Greek Manufacturing Sector». PhD thesis.

- ^ Zacharia, Zach G.; Sanders, Nada R.; Nix, Nancy W. (1 April 2011). «The Emerging Role of the Third-Party Logistics Provider (3PL) as an Orchestrator». Journal of Business Logistics. 32 (1): 40–54. doi:10.1111/j.2158-1592.2011.01004.x.

- ^ a b Raue, Jan Simon; Wieland, Andreas (2015). «The interplay of different types of governance in horizontal cooperations». The International Journal of Logistics Management. 26 (2): 401–423. doi:10.1108/IJLM-08-2012-0083. S2CID 166497725.

- ^ «Chartered Institute of Logistics and Transport (CILT) – Professional Logistics Programs». EduMaritime.

- ^ «Chartered Institute of Logistics & Transport Australia (CILTA) – Certification & Training». EduMaritime.

- ^ «Chartered Institute of Logistics and Transport in Hong Kong (CILTHK) – PQE Programs». EduMaritime.

- ^ «GIL HOME». Global Institute of Logistics. Retrieved 20 June 2019.

- ^ «International Association of Public Health Logisiticians». IAPHL. Retrieved 20 June 2019.

- ^ «Logistics Museum». logistics-museum.ru. Retrieved 20 June 2019.

- ^ «Museum of Logistics | 物流博物館». www.lmuse.or.jp. Retrieved 20 June 2019.

- ^ «Canadian Forces Logistics Museum». Montreal Museums. Archived from the original on 20 June 2019. Retrieved 20 June 2019.

Further reading[edit]

- Engels, Donald W. (1980). Alexander the Great and the Logistics of the Macedonian Army, University of California Press (194 pages). online

- Hess, Earl J. Civil War Logistics: A Study of Military Transportation (2017) online review

- Huston, James A. (1966). The Sinews of War: Army Logistics, 1775–1953, United States Army (789 pages). online

- Handfield, R.B., Straube, F., Pfohl, H.C. & Wieland, A., Trends and Strategies in Logistics and Supply Chain Management: Embracing Global Logistics Complexity to Drive Market Advantage, BVL 2013

- Ronald H. Ballou, Samir K. Srivastava, Business Logistics: Supply Chain Management, Pearson Education, 2007

- Donald Bowersox, David Closs, M. Bixby Cooper, Supply Chain Logistics Management, McGraw-Hill 2012

- M. Christopher: Logistics & Supply Chain Management: creating value-adding networks, Prentice Hall 2010. online

- J. V. Jones: Integrated Logistics Support Handbook, McGraw-Hill Logistics Series 2006

- B. S. Blanchard: Logistics Engineering and Management, Pearson Prentice Hall 2004

- R.G. Poluha: The Quintessence of Supply Chain Management: What You Really Need to Know to Manage Your Processes in Procurement, Manufacturing, Warehousing, and Logistics (Quintessence Series). First Edition. Springer Heidelberg New York Dordrecht London 2016. ISBN 978-3-662-48513-2

- Preclík Vratislav: Průmyslová logistika (Industrial logistics), 359 p., ISBN 80-01-03449-6, First issue Nakladatelství ČVUT v Praze, 2006, pp. 7 – 50, 63 – 73, 75 – 85, 123 – 347, Prague 2006

What is logistics? Same term, often different explanations. In a broad sense, logistics refers to the coordination and movement of goods or services from the point of origin to the point of destination. From a business perspective, logistics is an entire process that requires planning, implementing and controlling procedures that will ensure a smooth and seamless flow across all the stages of transportation.

The meaning of logistics

Origins

In Roman and Byzantine times, the title of the military administrative official was known as ‘’Logista’’.

The first theory of war based on the trinity of strategy, tactics, and logistics was created by Antoine-Henri Jomini, a Swiss officer who served as a general in the French army during Napoleon’s time. The concept of logistics also made its appearance in ‘’The Art of War’’, a book written by Baron Jomini himself.

Some claim the term ‘’logistics’’ comes from the French word ‘’Logistique’’ (translates to lodge) while others believe the word can be traced way back earlier to Greek origins, where the adjective ‘’logistikos’’ means ‘’skilled in calculating’’. Regardless of where or when the term itself was initially coined, what remains clear is that the concept of logistics was developed in the military, where there was a major need for strategy and management.

What is Logistics today

Due to an increased complexity of supplying different businesses with materials across a wide range of industries, logistics is no longer a straight-forward process. With the pressure of having the ‘’right item in the right quantity and the right time in the right place in the right condition for the right customer’’, the functions and forms of logistics have evolved dramatically.

Nowadays, logistics became an implementation of complex operations. Despite being a single component of a supply chain, the logistics of tangible goods involves the integration of information flow, material handling, security, production, packaging, inventory, warehousing and transportation. Formed of many different processes, aspects and forms, logistics can be described as the following but not limited to:

Inbound Logistics – One of the primary processes, inbound logistics refers to the activities of procuring material, handling and it is focused on the storage and transportation of incoming goods. For instance, a car manufacturing company will buy car parts from different locations, pick and transport them from different places with the end goal of assembling a car. The complete process that initially starts with material handling and end with storage and assembly refer to ‘’Inbound Logistics’’.

Outbound Logistics – Unlike inbound logistics that has a primary focus on procuring material and arranging the inbound movement of products from suppliers to manufacturing plants or warehouses, outbound logistics relies heavily on two aspects: transportation and storage of the final product. The transportation aspect is essential, moving the product from one location to another in the most effective way possible. While it may sound like an easy process, delaying a shipment can cost a company thousands. This is why it is important to plan ahead and consider different scenarios that may get in between and cause challenges during the movement of goods. On the other hand, to store products involves proper organization. The final product itself may require to be moved out to a customer unexpectedly, hence the reason why the products need to be safe and easily accessible.

Reverse Logistics – Also known as ‘’the process of moving goods from their point of destination with the purpose of capturing value or proper disposal’’. A relatively new term introduced in a white paper published by the Council of Mangement in 1992, reverse logistics basically refers to all the operations related to the reuse of products and materials. In other words, any process that happens after the product was already delivered it already involves reverse logistics. In a normal situation, if the product is damaged or defective, the customer would return it. Then the product would travel in reverse (the manufacturing firm would organize shipping, testing the product, repairing, disposing of the said product, etc) to retain any use left from the product itself.

Moving forward

Technological breakthroughs are changing different aspects of logistics as we know it. New innovations, business models and customer expectations are just some of the factors that are forcing the logistics industry to undergo major changes.

PwC makes a good point on what is logistics by exploring potential future scenarios. For instance, collaborative working could be one of the approaches to logistics, where incumbents would play a dominant role in using shared networks. Another possibility is that a need for crowd-sharing platforms increases, as start-ups drive technology development and innovations. The other scenario could be that large industrial and retail customers along with suppliers become the main players in the logistics market themselves, making use of some of the latest technologies, such as autonomous vehicles, warehouse robotic solutions or 3D printing. Finally, it could be the case that current market leaders could all compete for acquiring smaller players and achieve scale through consolidation and acquisition of innovative start-ups.

From machine learning to cloud technology and autonomous vehicles, the potential for digitization is huge but the lack of digital culture remains the biggest challenge in logistics. Regardless of what scenario could be more likely to take place in the future, something remains clear: smaller companies will need to be ‘digital fit’ and put their cultures to work.

Fundamentals

So in the end, what is logistics? Based on a study done by the Swedish Association of Road Haulage Companies in 2009, if an interruption or stoppage would occur in the truck transport service (which is naturally a part of the logistics chain), in less than a week some of the following events would take place: drinking water would be depleted, there will be a shortage of foods supplies, public transport discontinuing service and industrial production would stop. Beyond the process, the technical side, origins or its general meaning, logistics is basically ”the movement of life”.

-

1

logistics

logistics [ləˊdʒɪstɪks]

n pl

воен.тыл и снабже́ние, материа́льно-техни́ческое обеспе́чение, рабо́та ты́ла

Англо-русский словарь Мюллера > logistics

-

2

logistics

Персональный Сократ > logistics

-

3

logistics

logistics aerodrome

аэродром материально-технического обеспечения

English-Russian aviation dictionary > logistics

-

4

logistics

материально-техническое обеспечение, МТО; работа тыла; тыловое обеспечение

* * *

English-Russian military dictionary > logistics

-

5

logistics

1. n воен. тыл и снабжение

2. n воен. материально-техническое обеспечение

3. n воен. организация и осуществление работы тыла

4. n воен. спец. материально-техническое снабжение

5. n мат. логистика, математическая логика

English-Russian base dictionary > logistics

-

6

logistics

материально-техническое обеспечение; техника перевозок [транспортировки] и снабжения

Englsh-Russian aviation and space dictionary > logistics

-

7

logistics

English-Russian electronics dictionary > logistics

-

8

logistics

The New English-Russian Dictionary of Radio-electronics > logistics

-

9

logistics

English-Russian big medical dictionary > logistics

-

10

logistics

English-Russian big polytechnic dictionary > logistics

-

11

logistics

English-Russian dictionary of mechanical engineering and automation > logistics

-

12

logistics

L, logistics

материально-техническое обеспечение, МТО; тыловое обеспечение

————————

log, logistics

материально-техническое обеспечение, МТО; тыловое обеспечение

————————

logs, logistics

материально-техническое обеспечение, МТО; тыловое обеспечение

English-Russian dictionary of planing, cross-planing and slotting machines > logistics

-

13

logistics

сущ.

See:

* * *

* * *

логистика («служба тыла»)

материально-техническое снабжение контроль за движением физических материалов на предприятии; обычно подразделяется на управление материалами и управление распределением см. materials management см. distribution management

Англо-русский экономический словарь > logistics

-

14

logistics

Англо-русский синонимический словарь > logistics

-

15

logistics

Логистика, т. е. материально-техническое обеспечение. Слово logistic впервые появилось в XVII в., произойдя от греч. logos («слово», «мудрость»). Оно значило «логический». Впоследствии его стали использовать для обозначения определённого типа математической логики. Во множественном числе logistics употреблялось для различных типов арифметических действий, особенно для шестизначных вычислений, используемых в астрономии. Французы стали употреблять слово loguistique в XIX в. в значении обеспечения армии не только постоем, но и пищей, обмундированием и всем необходимым. Именно с этим значением слово logistic вошло в употребление американцев во времена Гражданской войны 1861-65 гг.. В Великобритании его стали употреблять лишь с 1993 г., когда различные армейские части, занимающиеся транспортом и обеспечением войск, были объединены в The Royal Logistic Corps (Королевский корпус по снабжению). С тех пор сфера употребления этого слова ещё более расширилась, и сейчас одно из его значений — перемещение людей или их вещей из одного пункта в другой с наибольшей эффективностью.

My family is scattered all over the world. Getting us all round the same table on Christmas Day is a major problem in logistics. — Члены моей семьи разбосаны по всему миру. Собрать всех нас за одним столом на Рождество — огромная техническая проблема.

English-Russian dictionary of expressions > logistics

-

16

logistics

материально-техническое обеспечение, МТО; инженерно-авиационное и тыловое обеспечение, ИАТО

computer aided logistics

up-front logistics

Авиасловарь > logistics

-

17

logistics

- техника снабжения

- логистика

логистика

система поставок

Совокупность методов и способов эффективного управления товарными потоками с обеспечением наименьших издержек и высокого уровня организации и осуществления процессов снабжения, управления товарным рынком, производства, сбыта и послепродажного обслуживания [http://www.integprog.ru/logistic/interlogistics/intro/a_logistics.html].

[ http://www.morepc.ru/dict/]

логистика

Планирование, контроль и управление транспортированием, складированием и другими материальными и нематериальными операциями, совершаемыми в процессе доведения сырья, материалов и полуфабрикатов до производства, в процессе самого производства и в процессе доведения готовой продукции до потребителя, а также управление соответствующими информационными потоками.

[ http://slovar-lopatnikov.ru/]Тематики

- информационные технологии в целом

- экономика

Синонимы

- система поставок

EN

- logistics

Англо-русский словарь нормативно-технической терминологии > logistics

-

18

logistics

Большой англо-русский и русско-английский словарь > logistics

-

19

logistics

Англо-русский технический словарь > logistics

-

20

logistics

1) материально-техническое снабжение

2) служба тыла

Англо-русский словарь по экономике и финансам > logistics

Страницы

- Следующая →

- 1

- 2

- 3

- 4

- 5

- 6

- 7

См. также в других словарях:

-

logistics — lo‧gis‧tics [ləˈdʒɪstɪks] noun [plural] TRANSPORT the arrangements that are needed for goods, materials, equipment, and people to be in the right place at the right time: • the logistics of shipping materials from Britain to Siberia reˌverse… … Financial and business terms

-

Logistics — Lo*gis tics, n. 1. (Mil.) That branch of the military art which embraces the details of moving and supplying armies. The meaning of the word is by some writers extended to include strategy. H. L. Scott. [1913 Webster] 2. By extension: The… … The Collaborative International Dictionary of English

-

logistics — art of moving, quartering, and supplying troops, 1879, from Fr. (l art) logistique (art) of quartering troops, from M.Fr. logis lodging, from O.Fr. logeiz shelter for an army, encampment, from loge (see LODGE (Cf. lodge) (n.)) + Greek derived… … Etymology dictionary

-

logistics — *strategy, tactics … New Dictionary of Synonyms

-

logistics — [n] management coordination, engineering, masterminding, organization, planning, plans, strategy, systematization; concept 660 … New thesaurus

-

logistics — [lō jis′tiks] n. [Fr logistique < logis, lodgings (< loger, to quarter: see LODGE): form as if < ML logisticus: see LOGISTIC2] 1. the branch of military science having to do with procuring, maintaining, and transporting materiel,… … English World dictionary

-

Logistics — For the drum and bass producer, see Logistics (artist). Public infrastructure Assets and facilities Airports · … Wikipedia

-

logistics — /loh jis tiks, leuh /, n. (used with a sing. or pl. v.) 1. the branch of military science and operations dealing with the procurement, supply, and maintenance of equipment, with the movement, evacuation, and hospitalization of personnel, with the … Universalium

-

Logistics — Мэтт Грешем Matt Gresham Дата рождения 1981 год(1981) Место рождения Кембридж Страна … Википедия

-

Logistics — The overall management of the way resources are obtained, stored and moved to the locations where they are required. Logistics management entails identifying potential suppliers and distributors; evaluating how accessible and effective they are… … Investment dictionary

-

logistics — lo|gis|tics [ləˈdʒıstıks US lou ] n [plural] [Date: 1800 1900; : French; Origin: logistique, from Greek logistike art of calculating , from logos; LOGIC] the practical arrangements that are needed in order to make a plan that involves a lot of… … Dictionary of contemporary English

What is logistics?

Have you ever wonder about the correct explanation for Logistics? The word “Logistics” first appeared in the Summary of the Art of War” book by Mr. Antoine-Henri Jomini, a military officer and a writer. It was attested to the English language in early 1846 from the French word ‘logistique’.

Logistics definition

The Oxford dictionary defines Logistics as ”the practical organization that is needed to make a complicated plan successful when a lot of people and equipment are involved” or “the business of transporting and delivering goods”.

In the military, Logistics was defined as “The discipline of planning and carrying out the movement, supply, and maintenance of military forces”, which was crucial during world war II. The word was added to the commercial world due to its importance from a point of production to the consumer.

In the commercial world, Logistics has given many definitions. Yet the bottom line is to improve the efficiency of the resources. Logistics of a value chain contain material handling including packing and labeling, transportation, warehousing, inventory management, demand projection, and procurement.

Looks like a simple process, but there is a lot to dig in within one element. Logistics play a crucial role to keep the world running. Most of the time, the Logistician does the hard work being backstage.

i.e. Consider a situation where person A in country B order a product from supplier C in country D. To deliver the product from country D to country B there is a lot of work involved.

First, this product should be produced. Supplier C has to purchase raw materials to produce the product. Then the product should pack and store until it is delivered. Then a booking has to make from a shipping line or from an airline.

Then the product should deliver to the airport or the seaport for transporting. Once the product is at the destination port, from the port it should deliver to the customer’s doorstep. So, there are a lot of logistics activities involved.

The undiscussed documentation process also has a lot more to do along with the risk mitigation throughout the flow.

There are arguments on giving a clear definition and setting a dedicated work to the word “Logistics”. Industry experts were confused on whether to place logistics as a sub-category of the supply chain or whether supply chain and Logistics are two different categories having common terms.

Yet there is no agreed work limit on whether Logistics is a sub-category of Supply Chain or two different terms with a common series of activities. Logistics is a very old term where the supply chain is a new concept.

Both terms target the smooth and efficient flow of products and services from the point of origin to the destination. I am keeping a question mark for you to decide what is best suited for Logistics.

Michael Kirby of National Distribution Centers defined Logistics and Supply Chain as “Supply chain management incorporates the field of logistics and logistics is a number of sub-processes within SCM,” confirming Logistics as a subcategory of Supply Chain.

Yet, Wayne Johnson of American Gypsum stated “There isn’t a difference today” saying Logistics and Supply Chain are the same.

Watch the video on youtube

7 Rights of Logistics

Logistics could be defined as a combination of 7 rights, where 7 rights include the right product, the right price, the right quantity, the right quality, the right place, the right customer, and the right time.

Right Product

The product should be the same as what the customer has ordered which is a basic requirement of placing orders by a customer. Placed orders should not substitute with other products.

Right Quality

Product quality is another key component in Logistics. There are different standards for different goods. Or there is a quality which customer demand for the payment they make in return. The quality of a product should not dissatisfy customers, It may make the customer satisfied or happy.

Right Quantity

The right quantity is the volume a customer has ordered. Receiving less than or more than the ordered quantity could become a burden to the customer. Receiving less will fail customers to cater to the market he/she is having a presence.

Right Price

The right price is the payment done for the valued customer receives with procuring a product or a service. The right price depends on the other 6 rights of Logistics.

Right Customer

The ordered products or services should reach the right customer who requires the products or the services. Receiving a product or a service to the wrong customer leads the right customer to be dissatisfied and fail the logistics of the product chain.

Right Time

The right product should be produced at the right time to cater to the demand. If jerseys are manufactured, the right time for them to be on the market is in the winter. If the product doesn’t reach the market prior to winter there won’t be a demand for the jerseys. Hence right time is very critical in Logistics

Right Place

The right place is the 7th right factor in logistics. Even the right product reaches the wrong place/market it won’t be easy to see the expected demand for the product. For example, ladies in some Asian countries wear sarees. The demand sarees have in Europe is not the same as in Asia. Hence the right place for sarees is the Asian market and not the European market.

Listen to the Audio of this Article

Related Articles- Reverse Logistics

Subscribe to our newsletter

To be updated with all the latest news, offers and special announcements.

Logistics is the process of planning and executing the efficient transportation and storage of goods from the point of origin to the point of consumption. The goal of logistics is to meet customer requirements in a timely, cost-effective manner.

Originally, logistics played the vital role of moving military personnel, equipment and goods. While logistics is as important as ever in the military, the term today is more commonly used in the context of moving commercial goods within the supply chain.

Many companies specialize in logistics, providing the service to manufacturers, retailers and other industries with a large need to transport goods. Some own the full gamut of infrastructure, from jet planes to trucks, warehouses and software, while others specialize in one or two parts. FedEx, UPS and DHL are well-known logistics providers.

Typically, large retailers or manufacturers own major parts of their logistics network. Most companies, however, outsource the function to third-party logistics providers (3PLs).

Functions of logistics

Transportation and warehousing are the two major functions of logistics.

Transportation management focuses on planning, optimizing and executing the use of vehicles to move goods between warehouses, retail locations and customers. The transportation is multimodal and can include ocean, air, rail and roads.

Not surprisingly, transportation management is a complex process that involves planning and optimizing routes and shipment loads, order management, freight auditing and payment. It can also extend to yard management, a process which oversees the movement of vehicles through the yards outside manufacturing plants, warehouses and distribution facilities. Carrier management is an important aspect since the price, availability and capacity of transportation carriers can vary widely.

Logistics companies typically use transportation management system (TMS) software to help meet the demands of transport-related logistics. There are also niche applications, such as yard management systems.

Warehousing, or warehouse management, includes such functions as inventory management and order fulfillment. It also involves managing warehouse infrastructure and processes — for example, in a fulfillment center, where orders for goods are received, processed and fulfilled (shipped to the customer). Most companies use warehouse management system (WMS) software to manage the flow and storage of goods and track inventory. Most vendors of enterprise resource planning (ERP) software offer TMS and WMS modules, as well as more specialized components for inventory management and other logistics functions.

Customs management, or global trade management, is often considered part of logistics since the paperwork to show compliance with government regulations must often be processed where goods cross national boarders or enter shipping ports.

Artificial intelligence (AI) and driverless vehicle technology will play important parts in how logistics operates in the future. Some logistics providers already use AI to better track packages and predict transport-related problems in the supply chain.

Meanwhile, autonomous vehicles, such as driverless forklifts, delivery trucks and drones, are likely to become more commonplace in warehouses, in warehouse yards and on highways.

Why logistics is important

While on-time delivery of intact packages has always been important throughout the supply chain, it has become even more mission-critical in recent years as omnichannel commerce, with its same-day home or retail delivery of customized products ordered from smartphones, becomes more common.

Suppliers, manufacturers, distributors and retailers have had to improve their logistics processes to meet the demand for quicker, more convenient delivery of a wider variety of goods. They also have had to better integrate their processes and systems to improve supply chain visibility.

Difference between logistics and supply chain management

Logistics management is an important component of supply chain management (SCM). While the terms are sometimes used interchangeably, logistics focuses on moving products and materials as efficiently as possible. In contrast, SCM encompasses a much broader range of supply chain planning (SCP) activities, such as demand planning and sales and operations planning (S&OP), and supply chain execution (SCE), including strategic sourcing and transportation management.

Sometimes, the terms inbound and outbound logistics are used to denote logistics for goods arriving at or leaving a facility, respectively. One important category is reverse logistics, the logistics processes needed to return a product for servicing, refurbishing or decommissioning and recycling.

This was last updated in October 2019

Continue Reading About logistics

- See how reverse logistics impacts e-commerce

- Understand how supply chain visibility improves logistics

- Self-driving trucks offer logistics efficiencies

- Sensors, big data enable predictive logistics

- Go inside global logistics providers FedEx and UPS

Dig Deeper on Supply chain and manufacturing

-

Learn the differences between 3PL and 4PL

By: Paul Maplesden

-

3PL brokerage vs. freight brokerage: Which fits your needs?

By: Paul Maplesden

-

Top 8 warehouse management systems to research

By: Linda Rosencrance

-

Digitizing the supply chain requires standards to succeed

By: Jim O’Donnell